76个工业组件库示例汇总

参数化三维产品设计组件 (注塑模具与公差分析)

概述

这是一个交互式的 Web 组件,旨在演示简单的三维零件(如带凸台的方块)的参数化设计过程,并结合注塑模具设计(如开模动画)与公差分析(如可视化公差带)的概念性可视化。

主要功能

- 参数化零件建模:

- 通过滑块实时修改零件的基础尺寸(宽度、高度、深度)。

- 通过滑块实时修改特征(圆柱凸台)的尺寸(直径、高度)和相对位置。

- 实时 3D 可视化:

- 使用 Three.js 渲染零件模型。

- 支持通过鼠标进行视图交互(旋转、缩放、平移)。

- 概念性分析与模拟:

- 公差可视化: 切换显示尺寸公差(最小/最大包络盒)和位置公差(特征允许范围)的理论边界。

- 模拟开模: 播放简化的动画,展示模具上下型腔分离的过程。

- 界面与风格:

- 采用苹果科技风格,界面简洁直观。

- 响应式布局,适应不同屏幕尺寸。

如何使用

- 打开页面: 在浏览器中打开

index.html文件。 - 调整参数:

- 在左侧面板的 “基础零件尺寸” 和 “特征: 圆柱凸台” 部分,拖动滑块调整零件的几何参数。

- 3D 模型会在释放滑块后更新。

- 交互视图:

- 在右侧 3D 视图区,按住鼠标 左键拖动 进行旋转。

- 滚动鼠标滚轮 进行缩放。

- 按住鼠标 右键 (或 Ctrl/Cmd + 左键) 拖动 进行平移。

- 公差分析 (概念):

- 在 “公差分析” 部分调整公差值滑块。

- 点击 “显示/隐藏公差范围” 按钮,切换显示红/绿/蓝色透明几何体,表示理论上的公差带。

- 模拟开模 (概念):

- 点击 “模拟开模 (概念)” 按钮,观看模具分离动画(零件会暂时隐藏)。

- 再次点击(按钮变为 “复位模具”) 可观看模具闭合动画,并重新显示零件。

- 重置视图: 点击 “重置视图” 按钮,将相机恢复到默认位置和朝向。

文件结构

parametric-3d-product-design/

├── index.html # HTML 页面结构

├── styles.css # CSS 样式定义

├── script.js # JavaScript 交互与3D逻辑

└── README.md # 本说明文件

技术栈

- HTML5 / CSS3 (Flexbox, CSS Variables)

- JavaScript (ES6+)

- Three.js (r128)

- Three.js OrbitControls

重要提示

- 概念演示: 本组件主要用于演示原理,并非精确的工程工具。

- 公差可视化: 仅为理论边界的概念性展示,不执行 实际的公差叠加或统计分析。

- 开模模拟: 动画效果高度简化,不涉及真实模具的复杂结构(如滑块、顶针、分型面细节等)。

- 几何模型: 零件由简单的几何体构成,未使用 CSG (构造实体几何) 进行精确合并,可能存在视觉穿插。如需精确模型,可考虑引入相关库。

- 性能: 频繁更新参数(尤其在公差可视化开启时)可能影响性能。

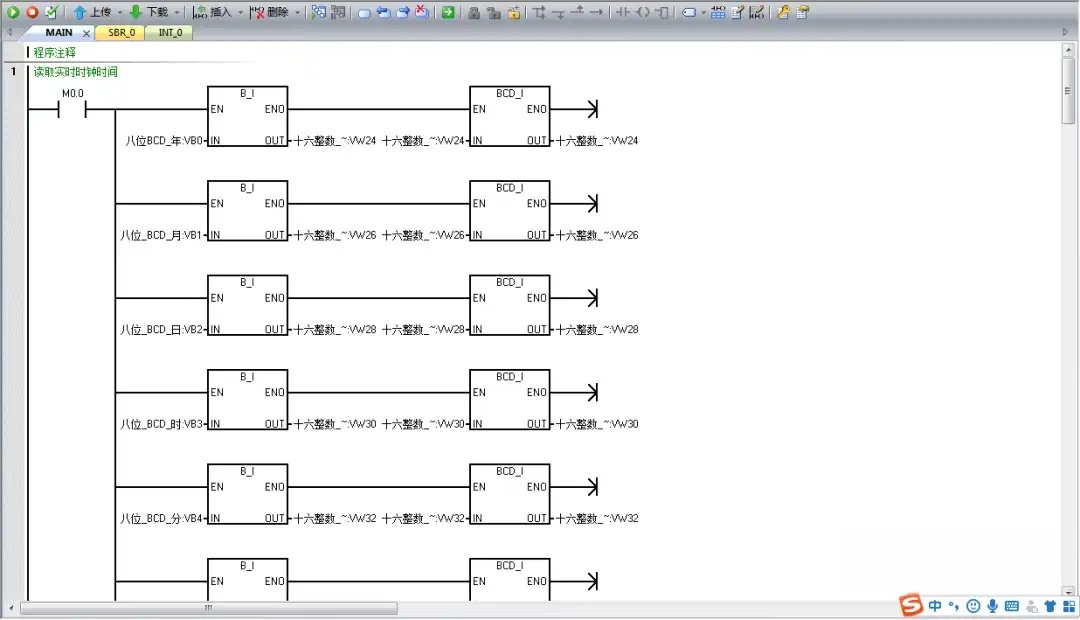

效果展示

源码

index.html

<!DOCTYPE html>

<html lang="zh-CN">

<head>

<meta charset="UTF-8">

<meta name="viewport" content="width=device-width, initial-scale=1.0">

<title>参数化三维产品设计 - 注塑模具与公差分析</title>

<link rel="stylesheet" href="styles.css">

<!-- 引入 Three.js -->

<script src="https://cdnjs.cloudflare.com/ajax/libs/three.js/r128/three.min.js"></script>

<!-- 引入 OrbitControls for camera interaction -->

<script src="https://cdn.jsdelivr.net/npm/three@0.128.0/examples/js/controls/OrbitControls.js"></script>

<!-- Optional: Add CSG library if needed for complex boolean operations -->

<!-- <script src="path/to/three-csg.js"></script> -->

</head>

<body>

<div class="product-design-container">

<header class="app-header">

<h1>参数化三维产品设计</h1>

<p>应用于注塑模具设计与公差分析</p>

</header>

<div class="main-content-area">

<!-- 左侧参数与控制面板 -->

<aside class="controls-panel">

<h2>参数定义 & 分析</h2>

<div class="parameter-section">

<h3>基础零件尺寸</h3>

<label for="partWidth">宽度 (X):</label>

<input type="range" id="partWidth" name="partWidth" min="20" max="100" value="50" step="1">

<span class="param-value" id="partWidthValue">50</span> mm

<label for="partHeight">高度 (Y):</label>

<input type="range" id="partHeight" name="partHeight" min="10" max="80" value="30" step="1">

<span class="param-value" id="partHeightValue">30</span> mm

<label for="partDepth">深度 (Z):</label>

<input type="range" id="partDepth" name="partDepth" min="20" max="100" value="40" step="1">

<span class="param-value" id="partDepthValue">40</span> mm

</div>

<div class="parameter-section">

<h3>特征: 圆柱凸台 (Boss)</h3>

<label for="bossDiameter">直径:</label>

<input type="range" id="bossDiameter" name="bossDiameter" min="5" max="25" value="15" step="0.5">

<span class="param-value" id="bossDiameterValue">15.0</span> mm

<label for="bossHeight">高度:</label>

<input type="range" id="bossHeight" name="bossHeight" min="2" max="20" value="10" step="0.5">

<span class="param-value" id="bossHeightValue">10.0</span> mm

<label for="bossPosX">X 位置 (%):</label> <!-- Position relative to width -->

<input type="range" id="bossPosX" name="bossPosX" min="10" max="90" value="50" step="1">

<span class="param-value" id="bossPosXValue">50</span> %

<label for="bossPosZ">Z 位置 (%):</label> <!-- Position relative to depth -->

<input type="range" id="bossPosZ" name="bossPosZ" min="10" max="90" value="50" step="1">

<span class="param-value" id="bossPosZValue">50</span> %

</div>

<div class="parameter-section">

<h3>公差分析 (概念)</h3>

<label for="dimensionTolerance">尺寸公差 (+/-):</label>

<input type="range" id="dimensionTolerance" name="dimensionTolerance" min="0.0" max="1.0" value="0.1" step="0.05">

<span class="param-value" id="dimensionToleranceValue">0.10</span> mm

<label for="positionTolerance">位置公差 (圆域 +/-):</label> <!-- Tolerance zone for boss position -->

<input type="range" id="positionTolerance" name="positionTolerance" min="0.0" max="0.5" value="0.05" step="0.01">

<span class="param-value" id="positionToleranceValue">0.05</span> mm

</div>

<div class="action-buttons">

<button id="analyzeToleranceButton">显示/隐藏公差范围</button>

<button id="simulateMoldButton">模拟开模 (概念)</button>

<button id="resetViewButton">重置视图</button>

</div>

<div class="status-display">

<h3>状态</h3>

<p id="statusText">准备就绪。请调整参数。</p>

</div>

</aside>

<!-- 右侧 3D 可视化区域 -->

<main class="visualization-area">

<div id="rendererContainer"></div>

<!-- Optional: Maybe add overlay for tolerance info -->

</main>

</div>

<footer class="app-footer">

<p>注塑模具设计与公差分析辅助组件</p>

</footer>

</div>

<script src="script.js"></script>

</body>

</html>

styles.css

/* styles.css - Parametric 3D Product Design Component */

:root {

--primary-bg: #ffffff;

--secondary-bg: #f5f5f7;

--controls-bg: #e8e8ed;

--text-primary: #1d1d1f;

--text-secondary: #515154;

--accent-blue: #007aff;

--accent-blue-hover: #005ec4;

--border-color: #d2d2d7;

--shadow-color: rgba(0, 0, 0, 0.08);

--apple-font: -apple-system, BlinkMacSystemFont, "Segoe UI", Roboto, Helvetica, Arial, sans-serif;

--tolerance-color-min: rgba(255, 0, 0, 0.3); /* Red tint for min */

--tolerance-color-max: rgba(0, 255, 0, 0.3); /* Green tint for max */

}

body {

font-family: var(--apple-font);

margin: 0;

background-color: var(--secondary-bg);

color: var(--text-primary);

font-size: 14px;

line-height: 1.5;

overflow-x: hidden;

}

.product-design-container {

width: 100%;

max-width: 100%;

min-height: calc(100vh - 40px);

display: flex;

flex-direction: column;

background-color: var(--primary-bg);

box-sizing: border-box;

}

.app-header {

background-color: var(--primary-bg);

text-align: center;

padding: 15px 20px;

border-bottom: 1px solid var(--border-color);

}

.app-header h1 {

margin: 0 0 5px 0;

font-size: 1.8em;

font-weight: 600;

color: var(--text-primary);

}

.app-header p {

margin: 0;

color: var(--text-secondary);

font-size: 0.9em;

}

.main-content-area {

flex-grow: 1;

display: flex;

width: 100%;

}

.controls-panel {

width: 340px; /* Slightly wider for more controls */

flex-shrink: 0;

background-color: var(--controls-bg);

padding: 20px;

border-right: 1px solid var(--border-color);

overflow-y: auto;

box-sizing: border-box;

max-height: calc(100vh - 100px); /* Adjust 100px based on header/footer */

}

.controls-panel h2 {

margin-top: 0;

margin-bottom: 25px;

font-size: 1.3em;

font-weight: 600;

color: var(--text-primary);

border-bottom: 1px solid #c8c8cc;

padding-bottom: 10px;

}

.parameter-section {

margin-bottom: 25px; /* Slightly less margin */

}

.parameter-section h3 {

margin-top: 0;

margin-bottom: 15px;

font-size: 1.0em;

font-weight: 600;

color: var(--text-secondary);

}

label {

display: block;

margin-bottom: 5px;

font-weight: 500;

color: var(--text-primary);

font-size: 0.95em;

}

input[type="range"] {

width: 100%;

height: 4px;

cursor: pointer;

appearance: none;

background: #dcdce0;

border-radius: 4px;

outline: none;

margin-bottom: 3px; /* Less space */

}

input[type="range"]::-webkit-slider-thumb {

appearance: none;

width: 16px;

height: 16px;

background: var(--accent-blue);

border-radius: 50%;

cursor: pointer;

}

input[type="range"]::-moz-range-thumb {

width: 16px;

height: 16px;

background: var(--accent-blue);

border-radius: 50%;

cursor: pointer;

border: none;

}

.param-value {

display: inline-block;

margin-right: 5px; /* Space before unit */

font-size: 0.9em;

color: var(--text-secondary);

min-width: 30px; /* Align values a bit */

text-align: right;

}

/* Style the unit text after span */

.parameter-section > span + span {

font-size: 0.85em;

color: var(--text-secondary);

margin-left: -2px; /* Pull unit closer */

margin-bottom: 15px;

display: inline-block;

}

.parameter-section label + input + span + span {

margin-bottom: 15px; /* Add bottom margin after unit */

}

select {

/* ... (same as previous component) ... */

width: 100%;

padding: 8px 10px;

border: 1px solid var(--border-color);

border-radius: 6px;

background-color: var(--primary-bg);

font-family: inherit;

font-size: 0.95em;

margin-bottom: 20px;

appearance: none;

background-image: url('data:image/svg+xml;charset=US-ASCII,%3Csvg%20width%3D%2220%22%20height%3D%2220%22%20xmlns%3D%22http%3A%2F%2Fwww.w3.org%2F2000%2Fsvg%22%3E%3Cpath%20d%3D%22M5%208l5%205%205-5z%22%20fill%3D%22%23515154%22%2F%3E%3C%2Fsvg%3E');

background-repeat: no-repeat;

background-position: right 10px center;

background-size: 12px;

}

.action-buttons button {

display: block;

width: 100%;

padding: 10px 15px;

margin-bottom: 10px;

font-size: 0.95em;

font-weight: 500;

color: #fff;

background-color: var(--accent-blue);

border: none;

border-radius: 6px;

cursor: pointer;

text-align: center;

transition: background-color 0.2s ease, box-shadow 0.2s ease;

}

.action-buttons button:hover {

background-color: var(--accent-blue-hover);

box-shadow: 0 2px 5px rgba(0, 122, 255, 0.2);

}

.action-buttons button:disabled {

background-color: #b0b0b5;

cursor: not-allowed;

box-shadow: none;

}

/* Style specific buttons */

#analyzeToleranceButton, #simulateMoldButton {

background-color: #5856d6; /* Purple accent */

transition: background-color 0.2s ease;

}

#analyzeToleranceButton:hover, #simulateMoldButton:hover {

background-color: #4341a0;

box-shadow: 0 2px 5px rgba(88, 86, 214, 0.2);;

}

#resetViewButton {

background-color: #6c757d;

}

#resetViewButton:hover {

background-color: #5a6268;

box-shadow: none;

}

.status-display {

margin-top: 20px;

padding-top: 15px;

border-top: 1px solid #c8c8cc;

}

.status-display h3 {

margin-top: 0;

margin-bottom: 10px;

font-size: 1.0em;

font-weight: 600;

color: var(--text-secondary);

}

#statusText {

font-size: 0.9em;

color: var(--text-primary);

min-height: 3em;

}

.visualization-area {

flex-grow: 1;

position: relative;

background-color: var(--secondary-bg);

overflow: hidden;

}

#rendererContainer {

position: absolute;

top: 0;

left: 0;

width: 100%;

height: 100%;

}

.app-footer {

text-align: center;

padding: 10px 20px;

border-top: 1px solid var(--border-color);

background-color: var(--primary-bg);

color: var(--text-secondary);

font-size: 0.85em;

}

/* Responsive adjustments */

@media (max-width: 768px) {

.main-content-area {

flex-direction: column;

}

.controls-panel {

width: 100%;

border-right: none;

border-bottom: 1px solid var(--border-color);

max-height: 60vh; /* Allow a bit more height for controls */

}

.visualization-area {

height: 40vh;

min-height: 250px;

}

.app-header h1 {

font-size: 1.5em;

}

}

script.js

// script.js - Parametric 3D Product Design Component

document.addEventListener('DOMContentLoaded', () => {

// --- DOM Elements ---

const rendererContainer = document.getElementById('rendererContainer');

const partWidthSlider = document.getElementById('partWidth');

const partHeightSlider = document.getElementById('partHeight');

const partDepthSlider = document.getElementById('partDepth');

const bossDiameterSlider = document.getElementById('bossDiameter');

const bossHeightSlider = document.getElementById('bossHeight');

const bossPosXSlider = document.getElementById('bossPosX');

const bossPosZSlider = document.getElementById('bossPosZ');

const dimensionToleranceSlider = document.getElementById('dimensionTolerance');

const positionToleranceSlider = document.getElementById('positionTolerance');

const partWidthValueSpan = document.getElementById('partWidthValue');

const partHeightValueSpan = document.getElementById('partHeightValue');

const partDepthValueSpan = document.getElementById('partDepthValue');

const bossDiameterValueSpan = document.getElementById('bossDiameterValue');

const bossHeightValueSpan = document.getElementById('bossHeightValue');

const bossPosXValueSpan = document.getElementById('bossPosXValue');

const bossPosZValueSpan = document.getElementById('bossPosZValue');

const dimensionToleranceValueSpan = document.getElementById('dimensionToleranceValue');

const positionToleranceValueSpan = document.getElementById('positionToleranceValue');

const analyzeToleranceButton = document.getElementById('analyzeToleranceButton');

const simulateMoldButton = document.getElementById('simulateMoldButton');

const resetViewButton = document.getElementById('resetViewButton');

const statusText = document.getElementById('statusText');

// --- Three.js Setup ---

let scene, camera, renderer, controls, partGroup, baseMesh, bossMesh;

let toleranceVizGroup, dimTolMeshMin, dimTolMeshMax, posTolViz;

let moldHalfTop, moldHalfBottom; // For mold simulation

let material, toleranceMaterialMin, toleranceMaterialMax, positionToleranceMaterial;

let isToleranceVisible = false;

let isMoldOpen = false;

let isAnimating = false;

// Conversion factor (e.g., if sliders are mm, and Three.js unit is meters)

// Let's work directly in 'mm' like units in Three.js for simplicity here.

const scaleFactor = 1;

function initThreeJS() {

// Scene

scene = new THREE.Scene();

scene.background = new THREE.Color(0xf5f5f7);

// Camera

const aspect = rendererContainer.clientWidth / rendererContainer.clientHeight;

camera = new THREE.PerspectiveCamera(50, aspect, 1, 2000); // Adjusted near/far

camera.position.set(100, 80, 150); // Adjusted for 'mm' scale

camera.lookAt(scene.position);

// Renderer

renderer = new THREE.WebGLRenderer({ antialias: true });

renderer.setSize(rendererContainer.clientWidth, rendererContainer.clientHeight);

renderer.setPixelRatio(window.devicePixelRatio);

rendererContainer.appendChild(renderer.domElement);

// Lights

const ambientLight = new THREE.AmbientLight(0xffffff, 0.6);

scene.add(ambientLight);

const keyLight = new THREE.DirectionalLight(0xffffff, 0.6);

keyLight.position.set(-50, 80, 50);

scene.add(keyLight);

const fillLight = new THREE.DirectionalLight(0xffffff, 0.3);

fillLight.position.set(50, 40, -30);

scene.add(fillLight);

// Controls

controls = new THREE.OrbitControls(camera, renderer.domElement);

controls.enableDamping = true;

controls.dampingFactor = 0.1;

// Materials

material = new THREE.MeshStandardMaterial({

color: 0x99999f, // Lighter gray plastic

metalness: 0.1,

roughness: 0.6,

polygonOffset: true, // Helps prevent z-fighting with tolerance viz

polygonOffsetFactor: 1,

polygonOffsetUnits: 1

});

// Tolerance Materials (Semi-transparent)

toleranceMaterialMin = new THREE.MeshBasicMaterial({

color: 0xff0000,

transparent: true,

opacity: 0.2,

side: THREE.DoubleSide,

depthWrite: false // Render after main object

});

toleranceMaterialMax = new THREE.MeshBasicMaterial({

color: 0x00ff00,

transparent: true,

opacity: 0.2,

side: THREE.DoubleSide,

depthWrite: false

});

positionToleranceMaterial = new THREE.MeshBasicMaterial({

color: 0x0000ff,

transparent: true,

opacity: 0.3,

side: THREE.DoubleSide,

depthWrite: false

});

// Part Group

partGroup = new THREE.Group();

scene.add(partGroup);

// Tolerance Visualization Group

toleranceVizGroup = new THREE.Group();

toleranceVizGroup.visible = false;

scene.add(toleranceVizGroup);

// Initial Part Creation

createPart();

// Start animation loop

animate();

}

// --- Parametric Part Generation ---

function createPart() {

// Clear previous part within the group

while (partGroup.children.length > 0) {

const child = partGroup.children[0];

partGroup.remove(child);

if (child.geometry) child.geometry.dispose();

}

// Get parameters

const width = parseFloat(partWidthSlider.value) * scaleFactor;

const height = parseFloat(partHeightSlider.value) * scaleFactor;

const depth = parseFloat(partDepthSlider.value) * scaleFactor;

const bossD = parseFloat(bossDiameterSlider.value) * scaleFactor;

const bossH = parseFloat(bossHeightSlider.value) * scaleFactor;

const bossPosXRatio = parseFloat(bossPosXSlider.value) / 100;

const bossPosZRatio = parseFloat(bossPosZSlider.value) / 100;

// Create Base Box

const baseGeom = new THREE.BoxGeometry(width, height, depth);

baseMesh = new THREE.Mesh(baseGeom, material);

// Position base so its bottom is at y=0

baseMesh.position.y = height / 2;

partGroup.add(baseMesh);

// Create Boss (Cylinder)

const bossGeom = new THREE.CylinderGeometry(bossD / 2, bossD / 2, bossH, 32);

bossMesh = new THREE.Mesh(bossGeom, material);

// Position Boss on top surface of the base

// Calculate position relative to the base center

const bossX = (bossPosXRatio - 0.5) * width;

const bossZ = (bossPosZRatio - 0.5) * depth;

bossMesh.position.set(bossX, height + bossH / 2, bossZ); // Y is base height + half boss height

bossMesh.rotation.x = 0; // Ensure cylinder is upright

partGroup.add(bossMesh);

// --- Update Tolerance Visualizations ---

// (Do this separately, only when needed, to avoid recreating on every param change)

if (isToleranceVisible) {

createToleranceVisualization(); // Recreate tolerance based on new nominal part

}

updateStatus("零件模型已更新。");

}

// --- Tolerance Visualization ---

function createToleranceVisualization() {

// Clear previous visualization

while (toleranceVizGroup.children.length > 0) {

const child = toleranceVizGroup.children[0];

toleranceVizGroup.remove(child);

if (child.geometry) child.geometry.dispose();

// Dispose materials if specific to tolerance viz? No, using shared ones.

}

const dimTol = parseFloat(dimensionToleranceSlider.value) * scaleFactor;

const posTol = parseFloat(positionToleranceSlider.value) * scaleFactor;

// Get current nominal dimensions

const width = parseFloat(partWidthSlider.value) * scaleFactor;

const height = parseFloat(partHeightSlider.value) * scaleFactor;

const depth = parseFloat(partDepthSlider.value) * scaleFactor;

const bossD = parseFloat(bossDiameterSlider.value) * scaleFactor;

const bossH = parseFloat(bossHeightSlider.value) * scaleFactor;

const bossX = (parseFloat(bossPosXSlider.value)/100 - 0.5) * width;

const bossZ = (parseFloat(bossPosZSlider.value)/100 - 0.5) * depth;

const bossNominalY = height + bossH / 2;

// 1. Dimension Tolerance (Min/Max Boxes for Base) - Conceptual

const baseMinGeom = new THREE.BoxGeometry(width - 2 * dimTol, height - 2 * dimTol, depth - 2 * dimTol);

dimTolMeshMin = new THREE.Mesh(baseMinGeom, toleranceMaterialMin);

dimTolMeshMin.position.y = (height - 2 * dimTol) / 2; // Adjust position for new height

toleranceVizGroup.add(dimTolMeshMin);

const baseMaxGeom = new THREE.BoxGeometry(width + 2 * dimTol, height + 2 * dimTol, depth + 2 * dimTol);

dimTolMeshMax = new THREE.Mesh(baseMaxGeom, toleranceMaterialMax);

dimTolMeshMax.position.y = (height + 2 * dimTol) / 2;

toleranceVizGroup.add(dimTolMeshMax);

// 2. Position Tolerance (Cylindrical Zone for Boss Centerline) - Conceptual

// Create a thin cylinder representing the tolerance zone diameter

const posTolGeom = new THREE.CylinderGeometry(posTol, posTol, height + bossH + dimTol * 2, 32); // Height spans base + boss + tolerance

posTolViz = new THREE.Mesh(posTolGeom, positionToleranceMaterial);

// Position it at the nominal boss X, Z, centered vertically within its height

posTolViz.position.set(bossX, (height + bossH + dimTol*2) / 2, bossZ);

toleranceVizGroup.add(posTolViz);

updateStatus("公差范围已更新。");

}

// --- Animation & Rendering Loop ---

function animate() {

requestAnimationFrame(animate);

controls.update();

renderer.render(scene, camera);

}

// --- Event Listeners ---

function setupEventListeners() {

// Parameter Sliders

const sliders = [partWidthSlider, partHeightSlider, partDepthSlider,

bossDiameterSlider, bossHeightSlider, bossPosXSlider, bossPosZSlider,

dimensionToleranceSlider, positionToleranceSlider];

sliders.forEach(slider => {

slider.addEventListener('input', handleSliderInput);

slider.addEventListener('change', handleSliderChange); // Update part only on release

});

// Action Buttons

analyzeToleranceButton.addEventListener('click', toggleToleranceAnalysis);

simulateMoldButton.addEventListener('click', simulateMoldOpening);

resetViewButton.addEventListener('click', resetCameraView);

// Window Resize

window.addEventListener('resize', onWindowResize);

}

function handleSliderInput(event) {

const sliderId = event.target.id;

const valueSpan = document.getElementById(sliderId + 'Value');

let value = parseFloat(event.target.value);

let unit = '';

// Determine unit and formatting

if (sliderId.includes('Tolerance')) {

valueSpan.textContent = value.toFixed(2);

unit = 'mm';

} else if (sliderId.includes('Pos')) {

valueSpan.textContent = value.toFixed(0);

unit = '%';

} else if (sliderId.includes('Diameter') || sliderId.includes('bossHeight')) {

valueSpan.textContent = value.toFixed(1);

unit = 'mm';

} else {

valueSpan.textContent = value.toFixed(0);

unit = 'mm';

}

// Find the next sibling span (if exists) to update unit? No, hardcoded in HTML.

// Live update for tolerance sliders if tolerance is visible

if (isToleranceVisible && (sliderId.includes('Tolerance') || sliderId.includes('Pos'))) {

createToleranceVisualization();

}

}

function handleSliderChange(event) {

// Recreate the main part geometry only when slider drag finishes

if (!isAnimating && !event.target.id.includes('Tolerance') && !event.target.id.includes('Pos')) {

createPart();

} else if (!isAnimating && (event.target.id.includes('Pos'))) {

// If only position changed, update part and tolerance if visible

createPart();

}

// Tolerance slider changes already handled live in input if visible

}

// --- Button Actions ---

function toggleToleranceAnalysis() {

isToleranceVisible = !isToleranceVisible;

if (isToleranceVisible) {

createToleranceVisualization();

toleranceVizGroup.visible = true;

analyzeToleranceButton.textContent = "隐藏公差范围";

updateStatus("显示公差范围 (概念性)。");

} else {

toleranceVizGroup.visible = false;

analyzeToleranceButton.textContent = "显示公差范围";

updateStatus("公差范围已隐藏。");

}

}

function simulateMoldOpening() {

if (isAnimating) return;

isAnimating = true;

simulateMoldButton.disabled = true;

resetViewButton.disabled = true;

analyzeToleranceButton.disabled = true;

// Simple simulation: create two halves and move them apart

if (!moldHalfTop || !moldHalfBottom) {

// Create conceptual mold halves (simple boxes)

const width = parseFloat(partWidthSlider.value) * scaleFactor + 20; // Mold bigger than part

const height = parseFloat(partHeightSlider.value) * scaleFactor / 2 + 20;

const depth = parseFloat(partDepthSlider.value) * scaleFactor + 20;

const moldMaterial = new THREE.MeshStandardMaterial({ color: 0x555555, metalness: 0.8, roughness: 0.5 });

const moldGeom = new THREE.BoxGeometry(width, height, depth);

moldHalfBottom = new THREE.Mesh(moldGeom, moldMaterial);

moldHalfTop = new THREE.Mesh(moldGeom, moldMaterial);

// Position halves relative to the part's center plane (y=height/2)

const partHeight = parseFloat(partHeightSlider.value) * scaleFactor;

moldHalfBottom.position.y = partHeight/2 - height/2; // Center of bottom mold half at part center plane - half mold height

moldHalfTop.position.y = partHeight/2 + height/2; // Center of top mold half at part center plane + half mold height

scene.add(moldHalfBottom);

scene.add(moldHalfTop);

partGroup.visible = false; // Hide original part

}

const targetSeparation = parseFloat(partHeightSlider.value) * scaleFactor * 1.5;

const startYTop = moldHalfTop.position.y;

const startYBottom = moldHalfBottom.position.y;

const targetYTop = startYTop + targetSeparation / 2;

const targetYBottom = startYBottom - targetSeparation / 2;

const duration = 1000; // ms

let startTime = null;

function moldStep(timestamp) {

if (!startTime) startTime = timestamp;

const elapsed = timestamp - startTime;

const progress = Math.min(elapsed / duration, 1);

const easedProgress = 0.5 - 0.5 * Math.cos(progress * Math.PI);

moldHalfTop.position.y = startYTop + (targetYTop - startYTop) * easedProgress;

moldHalfBottom.position.y = startYBottom + (targetYBottom - startYBottom) * easedProgress;

if (progress < 1) {

requestAnimationFrame(moldStep);

} else {

updateStatus("模拟开模完成。再次点击可复位。");

isAnimating = false;

simulateMoldButton.disabled = false;

resetViewButton.disabled = false;

analyzeToleranceButton.disabled = false;

isMoldOpen = true;

simulateMoldButton.textContent = "复位模具";

}

}

function resetMold() {

// Animation to close the mold

isAnimating = true;

simulateMoldButton.disabled = true;

resetViewButton.disabled = true;

analyzeToleranceButton.disabled = true;

const currentYTop = moldHalfTop.position.y;

const currentYBottom = moldHalfBottom.position.y;

// Calculate original positions correctly based on part height and mold height

const partHeight = parseFloat(partHeightSlider.value) * scaleFactor;

const moldHeight = parseFloat(partHeightSlider.value) * scaleFactor / 2 + 20;

const originalYTop = partHeight / 2 + moldHeight / 2;

const originalYBottom = partHeight / 2 - moldHeight / 2;

const durationClose = 800;

let startTimeClose = null;

function closeStep(timestamp) {

if (!startTimeClose) startTimeClose = timestamp;

const elapsed = timestamp - startTimeClose;

const progress = Math.min(elapsed / durationClose, 1);

const easedProgress = 0.5 - 0.5 * Math.cos(progress * Math.PI);

moldHalfTop.position.y = currentYTop + (originalYTop - currentYTop) * easedProgress;

moldHalfBottom.position.y = currentYBottom + (originalYBottom - currentYBottom) * easedProgress;

if (progress < 1) {

requestAnimationFrame(closeStep);

} else {

scene.remove(moldHalfTop);

scene.remove(moldHalfBottom);

moldHalfTop = null;

moldHalfBottom = null;

partGroup.visible = true; // Show part again

updateStatus("模具已复位。");

isAnimating = false;

simulateMoldButton.disabled = false;

resetViewButton.disabled = false;

analyzeToleranceButton.disabled = false;

isMoldOpen = false;

simulateMoldButton.textContent = "模拟开模 (概念)";

}

}

requestAnimationFrame(closeStep);

}

if (isMoldOpen) {

resetMold();

} else {

updateStatus("模拟开模过程...");

requestAnimationFrame(moldStep);

}

}

function resetCameraView() {

controls.reset();

// Adjust position based on current part size? Or fixed reset?

const currentHeight = parseFloat(partHeightSlider.value) * scaleFactor;

camera.position.set(100, 80 + currentHeight/2, 150);

camera.lookAt(0, currentHeight / 2, 0); // Look at center of base

controls.update();

updateStatus("视图已重置。");

}

// --- Utility Functions ---

function updateStatus(message) {

statusText.textContent = message;

console.log("Status:", message);

}

function onWindowResize() {

if (!renderer || !camera) return;

const width = rendererContainer.clientWidth;

const height = rendererContainer.clientHeight;

camera.aspect = width / height;

camera.updateProjectionMatrix();

renderer.setSize(width, height);

}

// --- Initialization Call ---

try {

initThreeJS();

setupEventListeners();

updateStatus("参数化产品设计组件初始化成功。");

} catch (error) {

console.error("初始化失败:", error);

updateStatus(`错误: ${error.message}`);

rendererContainer.innerHTML = `<p style='color: red; padding: 20px;'>无法加载3D视图。错误: ${error.message}</p>`;

}

});

![[特殊字符] 免税商品优选购物商城系统 | Java + SpringBoot + Vue | 前后端分离实战项目分享](https://i-blog.csdnimg.cn/direct/54982aae52634d5aaf6a6eaa6806fc85.png)